Considering the Basic Options for Ductwork Design

There are a lot of mathematical calculations involved in designing an effective and efficient ductwork system for a home. These will affect the specific details of a particular project. There are some essential “big picture” layout and design options that are common to most residential air distribution systems.

Let’s take a look at those major options and why your HVAC professional might recommend one or another for your home.

See Also: Products

Type of Ducts

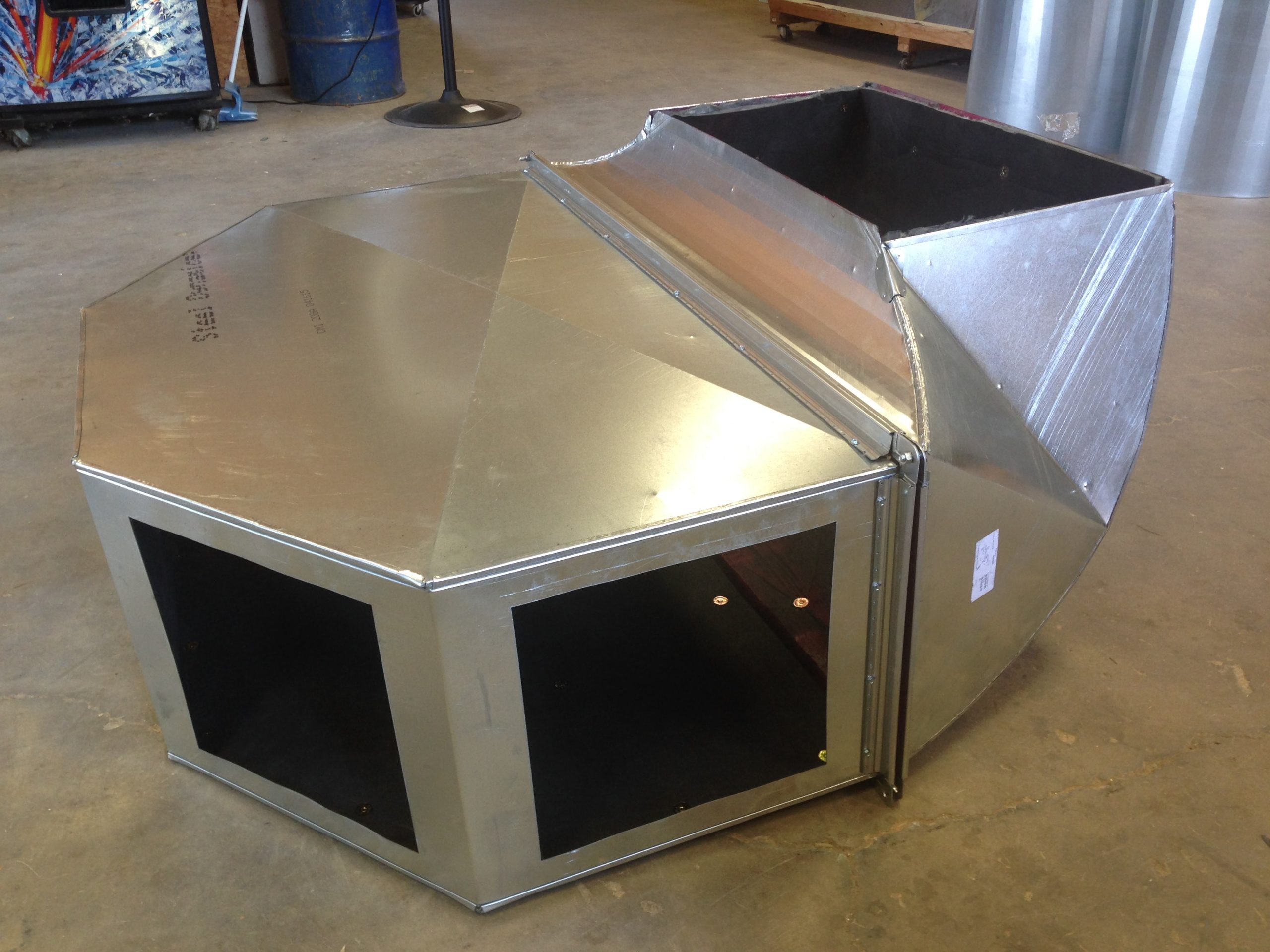

One big decision that needs to be made in designing an HVAC system is what type of duct to use. There are three basic kinds: flexible nonmetallic duct, fiberglass duct board, and sheet metal. Here at Conditioned Air Solutions, we only use flex duct and sheet metal—no duct board. Flex duct consists of a wire coil covered with pliable plastic, insulation, and an outer layer of vinyl or foil. Because it’s a bendable, stretchable tube, flex duct can be installed in difficult spaces. It’s extremely important that flex duct is installed properly. However, because if it sags or bends unnecessarily, it can seriously reduce the airflow through the system.

Sheet metal ducts are strong and durable. Plus, their inner surface is smooth, so air passing through them experiences less friction than in other kinds of ducts. That helps keep the air moving and air pressure up. Sheet metal ducts do need insulation if they’re installed in unconditioned space, like an attic or crawlspace. It’s important for them to sealed properly too. Otherwise, they can waste energy by losing heat in the winter and gaining heat in the summer.

Duct board is relatively inexpensive, but it has some serious downsides, which is why we don’t use it. It’s not as durable as sheet metal or flex duct, and it’s very easily damaged by water. If the lining does get damp due to condensation or other issues, it can become a perfect environment for mold growth. And you don’t want that in your air!

See Also: Conditioned Air Solutions Ductwork Shop

Supply Duct System Configurations

Another essential decision that needs to be made is the basic configuration of the supply duct system. There are at least four basic supply duct system designs: spider, radial, perimeter loop, and trunk and branch. The radial and trunk and branch are the ones most often used in residential HVAC. A trunk and branch system has a long main supply trunk (or two trunks, one going in each direction, if the HVAC unit is located near the center of the house). It runs the length of the house, with smaller branches and runouts leading off of it. ,While this is a very popular design, it can present a few challenges. One is that each trunk can only be, at most, about 24 feet long. Any longer than that, and the velocity of the air drops too much, leading to poor air flow.

Narrowing the size of the trunk as it gets further away from the HVAC unit can help to keep air velocity and pressure up. This requires some more complex design decisions to get the proportions right. With a radial system configuration, the branches or runouts are each connected directly to the air handler,. This is without a main supply trunk. Usually in this design the air handler centrally located in the house. The branches run out from it like the spokes of a wheel. Radial systems are primarily used in single-story homes. They have the advantage of maximizing air flow because the air blows directly down each branch. They do this without splitting off.

See Also: Why You Need a Duct Pressure Test

Return Duct Systems

Another basic decision involved in air distribution system design is the type of return duct system. There are two essential types: central and multiple-room. A central return system is the kind that most houses have. In this kind of system, there may be one or more return intake grilles. The key is that they’re centrally-located, often in a hallway or under a staircase. The central return intake is expected to draw air from all over the house. It is to keep air pressure and temperatures consistent. With multiple-story homes, it generally helps to have a central return intake on each floor. The problem is that if the air flow from a room or rooms is blocked. For instance, if interior doors are closed—then the central return can’t keep all of the air moving.

The multiple-room return duct system solves this problem, but it’s more complex and difficult to install. In a multiple-room system, there are return intakes in every room (or almost every room) that receives conditioned air. This ensures that the conditioned air never gets “stuck” in a room, keeping pressure imbalances to a minimum and evening out temperatures. Aside from the cost of design and installation, one other challenge of a multiple-room system is that it increases the impact of friction on the return air. That may mean the system requires a more powerful air handler to overcome that resistance.